Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

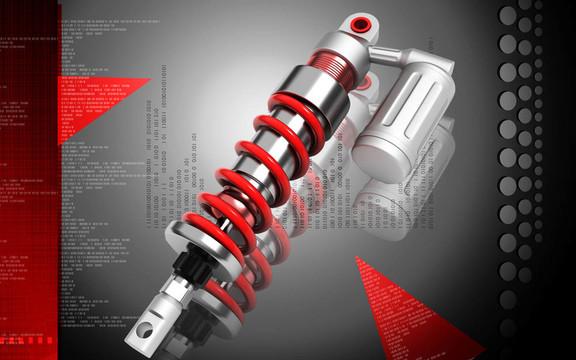

In our daily commutes, whether we are driving cars through city streets or riding high-speed trains to enjoy the lightning-fast speed, you might not have paid much attention. However, there is a key component that works silently all the time, ensuring our travel safety and comfort—it’s the shock absorber. Shock absorbers, which seem like an inconspicuous device on vehicles or equipment, play an irreplaceable role in reducing vibrations and enhancing stability.

The working principle of shock absorbers is based on a simple yet ingenious physical mechanism: converting the kinetic energy generated by vibrations into other forms of energy, thereby achieving the effect of damping. Taking the common hydraulic shock absorber as an example, its internal structure contains the secret of damping. When a vehicle travels on uneven roads, the wheels move up and down due to the undulations of the road surface, which are transmitted to the shock absorber through the suspension system. Inside the shock absorber, the piston moves up and down within the cylinder filled with hydraulic oil under the drive of the piston rod, causing the hydraulic oil to flow from one chamber through narrow orifices or throttle valves to another chamber. During this process, friction between the hydraulic oil and the walls of the orifice as well as among its own molecules generates a damping force. This damping force hinders the rapid movement of the piston, converting the kinetic energy of the vehicle’s vibrations into thermal energy, which is then dissipated into the surrounding air through the metal shell of the shock absorber, effectively suppressing the vibrations of the vehicle and reducing the repeated bouncing when the springs rebound, making the ride experience smoother. Air pressure shock absorbers, commonly found in some luxury cars, work differently. They mainly rely on the compression and expansion of gases to absorb vibration energy. When subjected to shock, the gas in the airbag or chamber within the shock absorber is compressed, storing energy; when the vibrations weaken, the gas expands and releases energy, thus cushioning the shocks. Compared to hydraulic shock absorbers, air pressure shock absorbers have a faster response speed and can react more quickly to changes in road conditions.

There are various types of shock absorbers, each with its own characteristics in terms of structure and performance.

A single-tube shock absorber has only one working cylinder and a more compact internal structure. It typically uses a combination of high-pressure gas and hydraulic oil to reduce the foam generated by the hydraulic oil during operation, thereby enhancing the response speed and damping force stability of the shock absorber. Single-tube shock absorbers perform better and can adapt to high-intensity use environments such as high-performance sports cars, racing cars, and high-end off-road vehicles. However, they have higher manufacturing costs and require strict requirements for production processes and sealing technology.

Adjustable hydraulic shock absorbers grant users the ability to adjust the damping force according to different driving conditions and personal preferences. The adjustment methods are divided into manual and electronic control. Manual adjustment involves rotating a knob on the shock absorber or using specialized tools to change the valve opening, thereby adjusting the hydraulic oil flow and the magnitude of the damping force; electronic control, on the other hand, utilizes the vehicle’s electronic control system to automatically adjust the working state of the shock absorber based on information such as vehicle speed, road conditions, and driving mode, providing drivers with a more personalized driving experience and is quite popular in high-end models and the aftermarket.

In the automotive suspension system, the shock absorber is an indispensable key component. It greatly enhances the ride comfort of the vehicle, reducing the bumps and vibrations experienced by passengers during driving. At the same time, it plays a significant role in the stability and safety of vehicle control. Good damping performance ensures that the tires always maintain good contact with the ground, increasing grip and making the vehicle more stable and reliable during driving, braking, and steering. Whether it’s frequent starts and stops on city roads or long-distance driving on highways, the shock absorber silently safeguards the smooth operation of the vehicle.

Shock absorbers are also widely used in industrial equipment such as cranes, elevators, and automated production lines. These devices generate significant vibrations and impacts during operation, which can affect the precision, stability, and service life of the equipment if not effectively controlled. Shock absorbers absorb and cushion vibration energy, protecting critical components of the equipment, reducing wear and failure, and ensuring the smooth progress of industrial production. For example, when a crane lifts heavy objects, shock absorbers reduce the impact on the crane structure during lifting and lowering, extending its service life and ensuring operational safety.

Taking high-speed trains as an example, the rapid speed of train operation places extremely high demands on stability. Devices such as hydraulic shock absorbers play a crucial role in effectively reducing train vibrations and snake-like swaying, ensuring smooth train operation and providing passengers with a comfortable riding environment. Just like Changchun Changbo Zhongbang Rail Transit Technology Co., Ltd., which focuses on producing, researching, and maintaining high-speed train accessories, hydraulic shock absorbers are one of the key products that contribute to the stable operation of high-speed trains.

Factors Affecting the Performance of Shock Absorbers

Enter your email address below and subscribe to our newsletter